Portwest A727 Combining Innovation and Total Safety

Innovative TPR design combined with a level E cut liner makes for an impact glove with exceptional dexterity, comfort and protection. The TPR pods are bonded directly on to the liner instead of traditional machine stitching which allows the glove to move freely with the hand.

EN 420, EN 388:2016, EN 407

Product Technical Information

Standards

-

ANSI/ISEA 105 - 2016 CUT Level A6

-

ANSI/ISEA 138 - 2019 Level 1 – Pass

-

EN 420

-

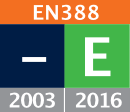

EN 388:2016 - 4.X.4.3.E.P

-

EN 407 X.1.X.X.X.X

Documentation

Protective Gloves : General Requirements

EN420 : 2003 + A1 2009

This standard defines the general requirements for glove design and construction, innocuousness, cleaning instructions, electrostatic properties, sizing, dexterity, water vapour transmission and absorption along with marking and information

EN 388

Gloves giving protection from mechanical risks

Protection against mechanical hazards is expressed by a pictogram followed by four numbers (performance levels), each representing test performance against a specific hazard.

1 Resistance to abrasion

Based on the number of cycles required to abrade through the sample glove (abrasion by sandpaper under a stipulated pressure). The protection factor is then indicated on a scale from 1 to 4 depending on how many revolutions are required to make a hole in the material. The higher the number, the better the glove. See table below.

2 Blade cut resistance

Based on the number of cycles required to cut through the sample at a constant speed. The protection factor is then indicated on a scale from 1 to 4.

3 Tear resistance

Based on the amount of force required to tear the sample.

The protection factor is then indicated on a scale from 1 to 4.

4 Puncture resistance

Based on the amount of force required to pierce the sample with a standard sized point. The protection factor is then indicated on a scale from 1 to 4.

EN 388:2016 ONLY

EN 388:2003 Standards specifies physical and mechanical aggression caused by abrasion, blade cut, tearing and puncture. EN388:2016 updates the existing standard with this new test method for abrasion, blade cut & impact resistance. EN ISO 13997:1999 (TDM Test) records cut results as a Newton value – the force of the blade on the glove material needed to cut through the material 20mm. The results are represented on a scale A-F.

5 Straight blade cut resistance EN 388:2016 ONLY

Based on the amount of force to achieve the moment of cut-through. The protection factor is then indicated on a scale from A to F

6 Impact resistance EN388:2016 ONLY

Impact-resistant properties to 5J, Performance Level P